charcoal making machine

charcoal production machine

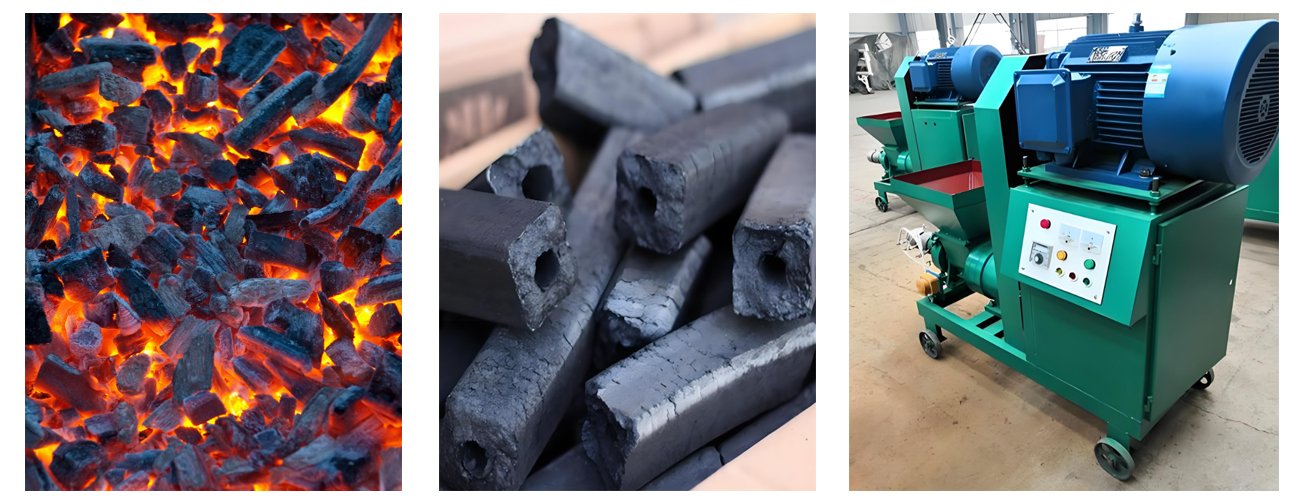

Charcoal machine is a kind of mechanical equipment to convert agricultural and forestry wastes (such as sawdust, straw, fruit shells, tree branches and other biomass raw materials) into mechanism charcoal, which has the characteristics of environmental protection, high efficiency, energy saving, etc., and is widely used in the fields of barbecue, metallurgy, heating, chemical industry and so on.

External dimensions:1800*700*1500MM

Equipment weight: 800KG

Equipped power: 18.5KW

Raw material humidity: 5% -12%

Production: 300-400kg/h

Table of Contents

- charcoal production machine

- How to make charcoal

- Which raw materials can make charcoal

- charcoal briquette machine Product Features

- Process of Charcoal Machine Production Line

- What are the performance characteristics of a charcoal processing machine?

- Supporting equipment for rice husk charcoal machineproduction line

How to make charcoal

A coal making machine is a machine that crushes raw materials into particles within 10mm, dries them into shape, and then puts them into a carbonization furnace for carbonization. The produced charcoal has high density, small volume, and good combustibility, and can replace firewood and coal.

The core principle of making charcoal is to expel volatile substances (e.g., moisture, tar, gases) from wood and other biomass through pyrolysis reactions at high temperatures and in an anoxic environment, leaving behind a solid product dominated by elemental carbon.

- Raw material pretreatment

- Crushing: The raw materials such as sawdust, straw, fruit shells and so on by using wood crusher to below 10mm particles.

- Drying: through the dryer to reduce the moisture content of raw materials to 8% -12%, to avoid moisture affect the quality of carbonization

- Rod Forming

- Equipment: Use of rod making machine (screw extrusion type or hydraulic type).

- Principle: Under high temperature and high pressure (about 300℃, 15-20MPa), the raw material is extruded into solid fuel in the form of rods (no need to add binder).

- Advantage: high density of formed charcoal, long burning time, and the utilization rate of raw material can reach more than 90%.

Which raw materials can make charcoal

Charcoal is manufactured from a wide range of raw materials, including natural wood and agricultural and forestry waste. These raw materials need to meet the conditions of high carbon content, moderate volatile substances and easy pyrolysis.

- Hardwoods: oak, birch, quercus, date palm, fruitwoods (e.g. applewood, pearwood), camphor wood, etc.

- Soft wood: pine, poplar, cedar, bamboo, etc.

- Forestry waste:

- Sawdust, wood chips (scraps from furniture factories, wood processing plants)

- Branches, bark, roots (residues from forestry pruning or harvesting)

- Bamboo shavings, bamboo nuggets (waste from processing bamboo products)

- Agricultural waste:

- Straw (corn stover, wheat straw, rice straw, etc.)

- Fruit shells (coconut shells, walnut shells, apricot shells, peach shells)

- Grain hulls (rice hulls, rice bran, peanut shells, cottonseed shells, etc.)

- Biomass raw materials:

- Sticks (waste substrate after cultivation of edible mushrooms, containing wood chips, cottonseed hulls, etc.)

- Animal manure (e.g., cow dung, horse dung, which needs to be mixed with wood chips to increase the carbon content)

- Pulp waste (e.g., waste paper, cardboard, which needs to be de-inked)

charcoal briquette machine Product Features

- Environmental protection and high efficiency

- Adopting high temperature and high pressure rod making process, combined with flue gas recovery technology, the production process has no dust emission, which is in line with national environmental protection standards.

- High utilization rate of raw materials, which can convert agricultural and forestry waste into high value-added products and reduce the waste of resources.

- Energy saving and consumption reduction

- Electromagnetic induction heating technology makes the temperature rise fast and stable, and reduces electricity consumption (average 35 kW/hour).

- Improved equipment to increase the pitch design, improve the feed volume, single-day output of up to 800-1000 pounds.

- Easy to operate

- Full-automatic control of electric heating device can randomly adjust the dryness and humidity of the material to ensure stable molding of the material.

Process of Charcoal Machine Production Line

| Crushing: This step is to crush the raw material powder into 5-10mm small particles Drying: Dry the crushed material to a suitable temperature to produce good charcoal. The humidity standard for raw materials is 8% -12%. Only when this humidity is reached can the rod be formed. Rod making: During the rod making process, the temperature must reach 300 ° C or above. If the temperature is too low, it is not easy to form, and if the temperature is too high, it will become soft. All must be adjusted to the appropriate temperature. Carbonization: Smokeless carbonization, using a carbonization furnace to carbonize semi-finished fuel rods, can achieve energy-saving and smokeless effects. Generally, it takes 8-12 hours. |

Molded charcoal display

What are the performance characteristics of a charcoal processing machine?

- This product is designed reasonably, manufactured with reliable quality, and has the characteristics of simple structure, convenient operation, small volume, small footprint, labor and electricity saving.

- The fully automatic control electric heating device designed can randomly adjust the dry and humidity of materials, ensuring stable discharge molding and improving work efficiency.

- The main parts of this product are made of wear-resistant materials that have undergone special treatment and can be continuously pressed for production, making it durable.

- Suitable for pressing and shaping various biomass raw materials, with low energy consumption and high production efficiency.

Supporting equipment for rice husk charcoal machineproduction line

Zhengzhou Fude Machinery Factory has been deeply involved in equipment manufacturing and has been operating in the industry for many years. Our main products include sawmills, slicers, crushers, branch crushers, charcoal machine production lines, and biomass pellet machines. We understand your needs and support customized equipment.

Fude Machinery-wood crusher manufacturer

Fude Machinery-wood crusher manufacturer